Description

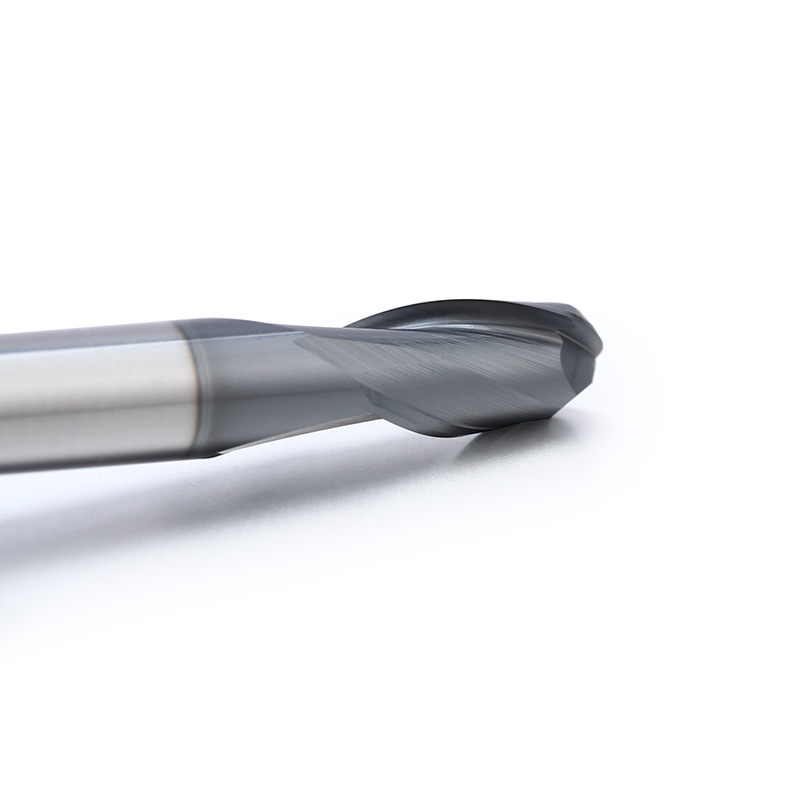

TEX Stainless Steel Carbide Ball Nose End Mills

TEX stainless steel carbide ball nose end mills is an general cutting tools, adopted ACO coating (dark gray color), has 2um coating thickness, HV4400 micro hardness, 0.5 coefficient of friction, strong adhesiveness and good wear-resisting property, the maximum working temperature can reach at 1100 celsius.

What is the coating ?

| Coating Type | Color | Micro Hardness (HV0.05) | Coating Thickness (um) | Friction Coefficient | Highest Working Temperature (Celsius) |

|---|---|---|---|---|---|

| TIN | Golden Yellow | 2400 | 1~7 | 0.35 | 600 |

| TiCN | Bluish-Grey | 3700 | 1~4 | 0.2 | 400 |

| TiCN-WP | Red-Copper | 3200 | 1~4 | 0.2 | 400 |

| TiAlN | Purplish-Red | 3300 | 1~4 | 0.4 | 800 |

| CrN | Silver | 1800 | 1~7 | 0.3 | 700 |

| ACO | Dark Grey | 4400 | 0.5~4 | 0.3 | 1100 |

| ALL | Copper | 4300 | 0.5~3 | 0.3 | 1000 |

| MDT | Rose-Purple | 3500~3800 | 1~4 | 0.25 | 800 |

| ATN | Grey-Black | 3500 | 0.5~4 | 0.25 | 900 |

| TiCrN-S | Silver/Gold | 3000 | 1~7 | 0.4 | 600 |

| AICrN-S | Grey-Black | 2500 | 1~2 | 0.4 | 1000 |

| TMAC | Bluish-Grey | 3300 | 0.4~4 | 0.3 | 1100 |

| ACS | Grey-Black | 3600 | 1~4 | 0.3 | 1100 |

| DLC | Grey-Black | 2500 | 1~5 | 0.1~0.2 | 350 |

| Ta-C | Muticolor | 5000 | 0.1~0.3 | 0.05~0.1 | 500 |

| NF1 | White-Gold | 2000 | 1~4 | 0.25 | 550 |

| nA-Bu | Blue-Purple | 4500 | 1~4 | 0.4 | 1200 |

How is the coating performance ?

| Coating Type | Properties | Applications |

|---|---|---|

| TiN | Excellent adhesion and fine surface finish | Applied to forming plastic injection molding, metal stamping, wear resistant coatings for machine components, No affection no original surface finish and suitable for mirror coating |

| TiCN | Wear-resisitant, low friction coeffcient | Applied to milling, press forming, tapping, injection molding and interrupted cutting |

| TiCN-MP | Excellent adhesion, excellent roughness,wear-resistant | Applied to interrupted cutting, milling, tapping, forming and stamping |

| TiAIN | High temperature resistance,wear resistant,excellent toughness and hardness,excellent adhesion | Applied to drilling, turning, high speed cutting,injection mold with glass fiber added |

| CrN | Excellent surface finish, strong self-lubricating,wear-resistant, corrosion-resistant,oxidation-resistant, excellent adhesion | Applied to copper tool, injection molding, corrosive plastic, components like mechanical axis, pin, can be performed with low temperature coating |

| ACO | High temperature resistant, oxidation-resistant, strong abrasive resistant | Applied to abrasive material above HRC55, especially applicable for high speed cutting and dry cutting which is dominant in tungsten carbide high speed drill |

| MDT | Excellent toughness, high micro hardness | Ideal coating for turning, drilling, milling and punching which is applicable for dry and wet high speed cutting |

| ATN | Excellent surface finish, high hardness, anti-sticking, low coefficient of friction | Suitable for machining stainless steel, Ti-alloy and tool steel |

| TiCrN | Easy-demold, low adhering, high wear-resistance,corrosion-resistant | Applied to injection mold, punching die, components and injection mold with glass fiber added |

| AICrN-S | Good for mould release, high wear resistance, corrosion resistance | Applied to plastic injection moulding to solve the problem of wear (e.g. glass fiber additive), corrosion and sticking |

| TMAC | Excellent heat temperature, oxidation resistance, high tenacity, wear-resistant | Applied to gaer hobs, punches, punchin die, drill , insert and mirror surface stainless steel which is widely used in cutting, punchin and AI die-casting |

| ACS | Anti corrosion, anti-soldering | Suitable for ZiNC and aluminum die , casting die, to solve the problem fo errosion, corrosion and soldering |

| DLC | Low friction cofficient, excellen adhesion, high lubrication | Applied to coating of mold, parts and medical device, expecially applicable for slide and nonferrous metal |

| Ta-C | High Hardness, excellent toughness, good lubrication | Applied to coating on tungsten carbide , Ta-c is widely used for cutting tools such as milling tool, micro drill and stamping die for processing non-ferrous metals like copper and aluminum |

| NF1 | Coating without Ti and Cr | Applied to plastic injection mold and silicon mold on anti-plastic sticking and also on aluminum copper and Titanum molding and its components |

| nA-Bu | High thermal performance, high hardness | Suitable for hard cutting, suitable for high requirements and general cutting conditions, apperance can be painted decorative blue |

What is the standard size ?

| Product Code | Radiu (R) | Diameter(D) | Cutting Length(H) | Overall Length(L) | Shank (d) |

|---|---|---|---|---|---|

| TEXB03010050 | 0.50 | 1.0 | 2.0 | 50 | 3 |

| TEXB04010050 | 0.50 | 1.0 | 2.0 | 50 | 4 |

| TEXB06010050 | 0.50 | 1.0 | 2.0 | 50 | 6 |

| TEXBL03010075 | 0.50 | 1.0 | 2.0 | 75 | 3 |

| TEXBL04010075 | 0.50 | 1.0 | 2.0 | 75 | 4 |

| TEXBL04010100 | 0.50 | 1.0 | 2.0 | 100 | 4 |

| TEXB03015050 | 0.75 | 1.5 | 3.0 | 50 | 3 |

| TEXB04015050 | 0.75 | 1.5 | 3.0 | 50 | 4 |

| TEXB06015050 | 0.75 | 1.5 | 3.0 | 50 | 6 |

| TEXBL03015075 | 0.75 | 1.5 | 3.0 | 75 | 3 |

| TEXBL04015075 | 0.75 | 1.5 | 3.0 | 75 | 4 |

| TEXBL04015100 | 0.75 | 1.5 | 3.0 | 100 | 4 |

| TEXB03020050 | 1.00 | 2.0 | 4.0 | 50 | 3 |

| TEXB04020050 | 1.00 | 2.0 | 4.0 | 50 | 4 |

| TEXB06020050 | 1.00 | 2.0 | 4.0 | 50 | 6 |

| TEXBL03020075 | 1.00 | 2.0 | 4.0 | 75 | 3 |

| TEXBL04020075 | 1.00 | 2.0 | 4.0 | 75 | 4 |

| TEXBL04020100 | 1.00 | 2.0 | 4.0 | 100 | 4 |

| TEXB03025050 | 1.25 | 2.5 | 5.0 | 50 | 3 |

| TEXB04025050 | 1.25 | 2.5 | 5.0 | 50 | 4 |

| TEXB06025050 | 1.25 | 2.5 | 5.0 | 50 | 6 |

| TEXBL03025075 | 1.25 | 2.5 | 5.0 | 75 | 3 |

| TEXBL04025075 | 1.25 | 2.5 | 5.0 | 75 | 4 |

| TEXBL04025100 | 1.25 | 2.5 | 5.0 | 100 | 4 |

| TEXB03030050 | 1.50 | 3.0 | 6.0 | 50 | 3 |

| TEXB04030050 | 1.50 | 3.0 | 6.0 | 50 | 4 |

| TEXB06030050 | 1.50 | 3.0 | 6.0 | 50 | 6 |

| TEXBL03030075 | 1.50 | 3.0 | 6.0 | 75 | 3 |

| TEXBL04030075 | 1.50 | 3.0 | 6.0 | 75 | 4 |

| TEXBL04030100 | 1.50 | 3.0 | 6.0 | 100 | 4 |

| TEXB04035050 | 1.75 | 3.5 | 7.0 | 50 | 4 |

| TEXB06035050 | 1.75 | 3.5 | 7.0 | 50 | 6 |

| TEXBL04035075 | 1.75 | 3.5 | 7.0 | 75 | 4 |

| TEXBL04035100 | 1.75 | 3.5 | 7.0 | 100 | 4 |

| TEXB04040050 | 2.00 | 4.0 | 8.0 | 50 | 4 |

| TEXB06040050 | 2.00 | 4.0 | 8.0 | 50 | 6 |

| TEXBL04040075 | 2.00 | 4.0 | 8.0 | 75 | 4 |

| TEXBL04040100 | 2.00 | 4.0 | 8.0 | 100 | 4 |

| TEXB06045050 | 2.25 | 4.5 | 9.0 | 50 | 6 |

| TEXBL06045075 | 2.25 | 4.5 | 9.0 | 75 | 6 |

| TEXBL06045100 | 2.25 | 4.5 | 9.0 | 100 | 6 |

| TEXB06050050 | 2.50 | 5.0 | 10.0 | 50 | 6 |

| TEXBL06050075 | 2.50 | 5.0 | 10.0 | 75 | 6 |

| TEXBL06050100 | 2.50 | 5.0 | 10.0 | 100 | 6 |

| TEXB06055050 | 2.75 | 5.5 | 11.0 | 50 | 6 |

| TEXBL06055075 | 2.75 | 5.5 | 11.0 | 75 | 6 |

| TEXBL06055100 | 2.75 | 5.5 | 11.0 | 100 | 6 |

| TEXB06060050 | 3.00 | 6.0 | 12.0 | 50 | 6 |

| TEXBL06060075 | 3.00 | 6.0 | 12.0 | 75 | 6 |

| TEXBL06060100 | 3.00 | 6.0 | 12.0 | 100 | 6 |

| TEXBL06060150 | 3.00 | 6.0 | 12.0 | 150 | 6 |

| TEXB08065060 | 3.25 | 6.5 | 13.0 | 60 | 8 |

| TEXB08070060 | 3.50 | 7.0 | 14.0 | 60 | 8 |

| TEXB08075060 | 3.75 | 7.5 | 15.0 | 60 | 8 |

| TEXB08080060 | 4.00 | 8.0 | 16.0 | 60 | 8 |

| TEXBL08080075 | 4.00 | 8.0 | 16.0 | 75 | 8 |

| TEXBL08080100 | 4.00 | 8.0 | 16.0 | 100 | 8 |

| TEXBL08080150 | 4.00 | 8.0 | 16.0 | 150 | 8 |

| TEXB10090075 | 4.50 | 9.0 | 18.0 | 75 | 10 |

| TEXB10100075 | 5.00 | 10.0 | 20.0 | 75 | 10 |

| TEXBL10100100 | 5.00 | 10.0 | 20.0 | 100 | 10 |

| TEXBL10100150 | 5.00 | 10.0 | 20.0 | 150 | 10 |

| TEXB12120075 | 6.00 | 12.0 | 25.0 | 75 | 12 |

| TEXBL12120100 | 6.00 | 12.0 | 25.0 | 100 | 12.0 |

| TEXBL12120150 | 6.00 | 12.0 | 25.0 | 150 | 12.0 |

| TEXB14140100 | 7.00 | 14.0 | 40.0 | 100 | 14 |

| TEXBL14140150 | 7.00 | 14.0 | 40.0 | 150 | 14.0 |

| TEXB16160100 | 8.00 | 16.0 | 40.0 | 100 | 16 |

| TEXBL16160150 | 8.00 | 16.0 | 40.0 | 150 | 16.0 |

| TEXB18180100 | 9.00 | 18.0 | 40.0 | 100 | 18 |

| TEXBL18180150 | 9.00 | 18.0 | 40.0 | 150 | 18.0 |

| TEXB20200100 | 10.00 | 20.0 | 40.0 | 100 | 20 |

| TEXBL20200150 | 10.00 | 20.0 | 40.0 | 150 | 20.0 |

| TEXB25250100 | 12.50 | 25.0 | 40.0 | 100 | 25 |

What is the tolerance ?

| Cutting Diameter | Cutting Blade Tolerance | Shank Tolerance |

|---|---|---|

| D17.0~20.0mm | -0.015~-0.045mm | H6 |

| D11.0~16.0mm | -0.01~-0.04mm | H6 |

| D6.5~10.5mm | -0.01~-0.035mm | H6 |

| D3.0~6.0mm | -0.01~-0.03mm | H6 |

| D1.0~2.9mm | 0~-0.02mm | H6 |

What is the suitable machining material ?

| P20 S45C | SCM SK | FC FCD | CU | 304 SS | Ti |

|---|---|---|---|---|---|

| * | * | * | * | * | * |

| Carbon Steel | Alloy Steel | Cast Iron | Copper Alloy | 304 Stainless Steel | Ti Alloy |

Reviews

There are no reviews yet.