Description

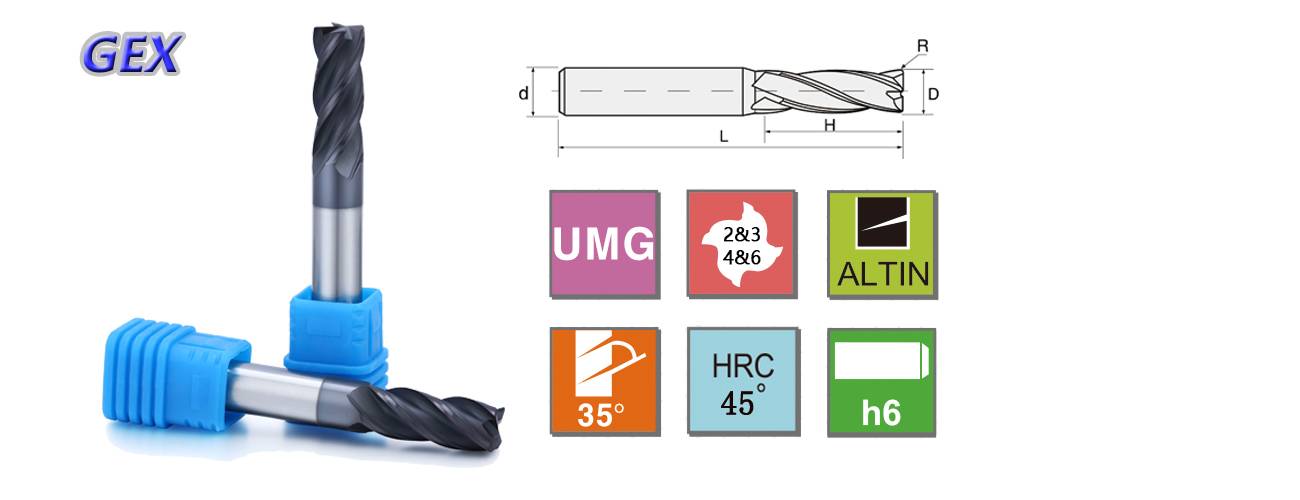

GEX Carbide Corner Radius End Mills

GEX carbide corner radius end mills is an economical cutting tools, adopted AITIN-L coating (black color), has 2um coating thickness, HV3000 micro hardness, 0.35 coefficient of friction, strong universal property and good wear-resisting property, the maximum working temperature can reach at 800 celsius.

What is the coating ?

| Coating Type | Color | Micro Hardness (HV0.05) | Coating Thickness (um) | Friction Coefficient | Highest Working Temperature (Celsius) |

|---|---|---|---|---|---|

| TIN | Golden Yellow | 2400 | 1~7 | 0.35 | 600 |

| TiCN | Bluish-Grey | 3700 | 1~4 | 0.2 | 400 |

| TiCN-WP | Red-Copper | 3200 | 1~4 | 0.2 | 400 |

| TiAlN | Purplish-Red | 3300 | 1~4 | 0.4 | 800 |

| CrN | Silver | 1800 | 1~7 | 0.3 | 700 |

| ACO | Dark Grey | 4400 | 0.5~4 | 0.3 | 1100 |

| ALL | Copper | 4300 | 0.5~3 | 0.3 | 1000 |

| MDT | Rose-Purple | 3500~3800 | 1~4 | 0.25 | 800 |

| ATN | Grey-Black | 3500 | 0.5~4 | 0.25 | 900 |

| TiCrN-S | Silver/Gold | 3000 | 1~7 | 0.4 | 600 |

| AICrN-S | Grey-Black | 2500 | 1~2 | 0.4 | 1000 |

| TMAC | Bluish-Grey | 3300 | 0.4~4 | 0.3 | 1100 |

| ACS | Grey-Black | 3600 | 1~4 | 0.3 | 1100 |

| DLC | Grey-Black | 2500 | 1~5 | 0.1~0.2 | 350 |

| Ta-C | Muticolor | 5000 | 0.1~0.3 | 0.05~0.1 | 500 |

| NF1 | White-Gold | 2000 | 1~4 | 0.25 | 550 |

| nA-Bu | Blue-Purple | 4500 | 1~4 | 0.4 | 1200 |

How is the coating performance ?

| Coating Type | Properties | Applications |

|---|---|---|

| TiN | Excellent adhesion and fine surface finish | Applied to forming plastic injection molding, metal stamping, wear resistant coatings for machine components, No affection no original surface finish and suitable for mirror coating |

| TiCN | Wear-resisitant, low friction coeffcient | Applied to milling, press forming, tapping, injection molding and interrupted cutting |

| TiCN-MP | Excellent adhesion, excellent roughness,wear-resistant | Applied to interrupted cutting, milling, tapping, forming and stamping |

| TiAIN | High temperature resistance,wear resistant,excellent toughness and hardness,excellent adhesion | Applied to drilling, turning, high speed cutting,injection mold with glass fiber added |

| CrN | Excellent surface finish, strong self-lubricating,wear-resistant, corrosion-resistant,oxidation-resistant, excellent adhesion | Applied to copper tool, injection molding, corrosive plastic, components like mechanical axis, pin, can be performed with low temperature coating |

| ACO | High temperature resistant, oxidation-resistant, strong abrasive resistant | Applied to abrasive material above HRC55, especially applicable for high speed cutting and dry cutting which is dominant in tungsten carbide high speed drill |

| MDT | Excellent toughness, high micro hardness | Ideal coating for turning, drilling, milling and punching which is applicable for dry and wet high speed cutting |

| ATN | Excellent surface finish, high hardness, anti-sticking, low coefficient of friction | Suitable for machining stainless steel, Ti-alloy and tool steel |

| TiCrN | Easy-demold, low adhering, high wear-resistance,corrosion-resistant | Applied to injection mold, punching die, components and injection mold with glass fiber added |

| AICrN-S | Good for mould release, high wear resistance, corrosion resistance | Applied to plastic injection moulding to solve the problem of wear (e.g. glass fiber additive), corrosion and sticking |

| TMAC | Excellent heat temperature, oxidation resistance, high tenacity, wear-resistant | Applied to gaer hobs, punches, punchin die, drill , insert and mirror surface stainless steel which is widely used in cutting, punchin and AI die-casting |

| ACS | Anti corrosion, anti-soldering | Suitable for ZiNC and aluminum die , casting die, to solve the problem fo errosion, corrosion and soldering |

| DLC | Low friction cofficient, excellen adhesion, high lubrication | Applied to coating of mold, parts and medical device, expecially applicable for slide and nonferrous metal |

| Ta-C | High Hardness, excellent toughness, good lubrication | Applied to coating on tungsten carbide , Ta-c is widely used for cutting tools such as milling tool, micro drill and stamping die for processing non-ferrous metals like copper and aluminum |

| NF1 | Coating without Ti and Cr | Applied to plastic injection mold and silicon mold on anti-plastic sticking and also on aluminum copper and Titanum molding and its components |

| nA-Bu | High thermal performance, high hardness | Suitable for hard cutting, suitable for high requirements and general cutting conditions, apperance can be painted decorative blue |

What is the standard size ?

| Product Code | Radius (R) | Diameter (D) | Cutting Length (H) | Overall Length (L) | Shank (d) |

|---|---|---|---|---|---|

| GEXCR0302002050 | 0.20 | 2.0 | 6.0 | 50 | 3 |

| GEXCR0302005050 | 0.50 | 2.0 | 6.0 | 50 | 3 |

| GEXCR0302502050 | 0.20 | 2.5 | 8.0 | 50 | 3 |

| GEXCR0302505050 | 0.50 | 2.5 | 8.0 | 50 | 3 |

| GEXCR0303002050 | 0.20 | 3.0 | 8.0 | 50 | 3 |

| GEXCR0303005050 | 0.50 | 3.0 | 8.0 | 50 | 3 |

| GEXCR0303010050 | 1.00 | 3.0 | 8.0 | 50 | 3 |

| GEXCR0401002050 | 0.20 | 1.0 | 3.0 | 50 | 4 |

| GEXCR0401502050 | 0.20 | 1.5 | 4.0 | 50 | 4 |

| GEXCR0401505050 | 0.50 | 1.5 | 4.0 | 50 | 4 |

| GEXCR0402002050 | 0.20 | 2.0 | 6.0 | 50 | 4 |

| GEXCR0402005050 | 0.50 | 2.0 | 6.0 | 50 | 4 |

| GEXCR0402502050 | 0.20 | 2.5 | 8.0 | 50 | 4 |

| GEXCR0402505050 | 0.50 | 2.5 | 8.0 | 50 | 4 |

| GEXCR0403002050 | 0.20 | 3.0 | 8.0 | 50 | 4 |

| GEXCR0403005050 | 0.50 | 3.0 | 8.0 | 50 | 4 |

| GEXCR0403010050 | 1.00 | 3.0 | 8.0 | 50 | 4 |

| GEXCR0404002050 | 0.20 | 4.0 | 11.0 | 50 | 4 |

| GEXCR0404005050 | 0.50 | 4.0 | 11.0 | 50 | 4 |

| GEXCR0404010050 | 1.00 | 4.0 | 11.0 | 50 | 4 |

| GEXCR0605005050 | 0.50 | 5.0 | 15.0 | 50 | 6 |

| GEXCR0605010050 | 1.00 | 5.0 | 15.0 | 50 | 6 |

| GEXCR0606002050 | 0.20 | 6.0 | 15.0 | 50 | 6 |

| GEXCR0606005050 | 0.50 | 6.0 | 15.0 | 50 | 6 |

| GEXCR0606010050 | 1.00 | 6.0 | 15.0 | 50 | 6 |

| GEXCR0606015050 | 1.50 | 6.0 | 15.0 | 50 | 6 |

| GEXCR0606020050 | 2.00 | 6.0 | 15.0 | 50 | 6 |

| GEXCR0808005050 | 0.50 | 8.0 | 20.0 | 60 | 8 |

| GEXCR0808010050 | 1.00 | 8.0 | 20.0 | 60 | 8 |

| GEXCR0808015050 | 1.50 | 8.0 | 20.0 | 60 | 8 |

| GEXCR0808020050 | 2.00 | 8.0 | 20.0 | 60 | 8 |

| GEXCR1010005075 | 0.50 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1010010075 | 1.00 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1010015075 | 1.50 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1010020075 | 2.00 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1010025075 | 2.50 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1010030075 | 3.00 | 10.0 | 25.0 | 75 | 10 |

| GEXCR1212005075 | 0.50 | 12.0 | 30.0 | 75 | 12.0 |

| GEXCR1212010075 | 1.00 | 12.0 | 30.0 | 75 | 12.0 |

| GEXCR1212015075 | 1.50 | 12.0 | 30.0 | 75 | 12.0 |

| GEXCR1212020075 | 2.00 | 12.0 | 30.0 | 75 | 12.0 |

| GEXCR1212025075 | 2.50 | 12.0 | 30.0 | 75 | 12.0 |

| GEXCR1212030075 | 3.00 | 12.0 | 30.0 | 75 | 12.0 |

What is the tolerance ?

| Cutting Diameter | Cutting Blade Tolerance | Shank Tolerance |

|---|---|---|

| D17.0~20.0mm | -0.015~-0.045mm | H6 |

| D11.0~16.0mm | -0.01~-0.04mm | H6 |

| D6.5~10.5mm | -0.01~-0.035mm | H6 |

| D3.0~6.0mm | -0.01~-0.03mm | H6 |

| D1.0~2.9mm | 0~-0.02mm | H6 |

What is the suitable machining material ?

| P20 S45C | SCM SK | FC FCD | CU |

|---|---|---|---|

| * | * | * | * |

| Carbon Steel | Alloy Steel | Cast Iron | Copper Alloy |

Reviews

There are no reviews yet.